S2K Commerce - Products Dropdown

S2K Commerce - Shopping Cart

S2K Commerce - Order Entry

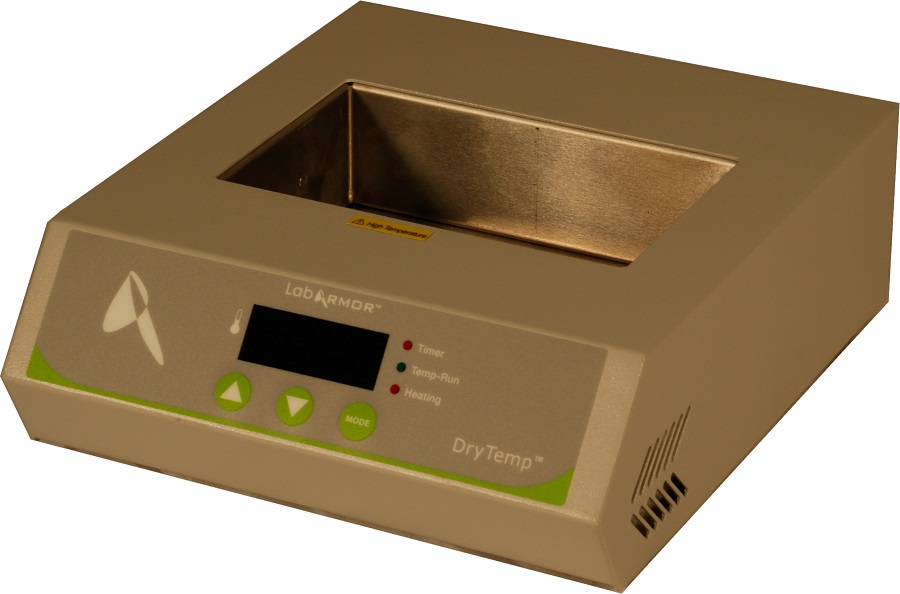

DryTemp Dry Bath

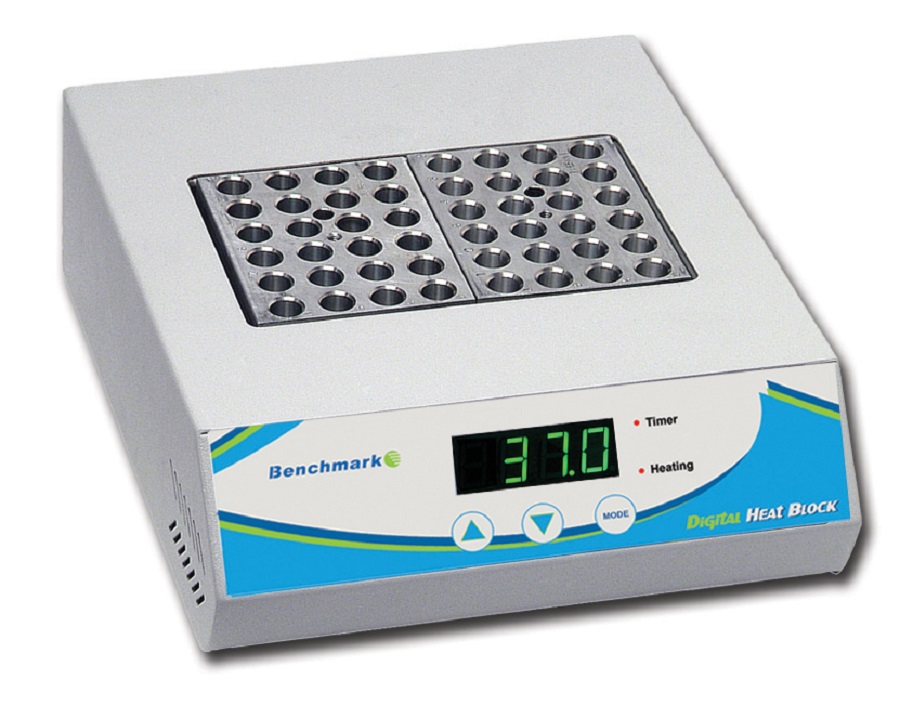

The Benchmark series of digital dry baths offer digital control over both temperature and time, eliminating the need for an external thermometer

or timer. Available in three configurations, the digital dry baths offer capacity for up to four blocks. They are extremely space efficient. (The four block model can accommodate up to 96x1.5ml tubes in less than a square foot of bench space.)

The cavities of the high grade aluminum blocks are precision machined to match the conical size and shape of 0.5, 1.5, 2.0, 15 and 50ml tube sizes, providing unsurpassed temperature uniformity. Assorted blocks are available for compatibility with nearly all common tube sizes. Custom blocks are also

available upon request, please check Benchmark's web site for a list of all available blocks.

All Benchmark dry baths offer a built-in user recalibration function, to guarantee long term temperature accuracy. Each dry bath includes an

easy to use block lifter, with a temperature insulated handle for quick, convenient exchange of blocks, even while they're still hot.

| Temp. Range | Ambient +5 to 150°C |

| Temp. Accuracy | ± 0.2°C |

| Temp. Increments | 0.1°C |

| Temp. Uniformity | ± 0.2°C |

| Block Construction | High Grade Aluminum |

| Warranty | 2 years |

| Timer | 1 to 999 min. |

| Dimensions | 7.8 x 9 x 3.2 in. / 20 x 23 x 8 cm 8.7 x 10 x 3.2 in. / 22 x 26 x 8 cm 8.7 x 14 x 3.2 in. / 22 x 36 x 8 |

| Electrical | 115V or 230V / 50-60 Hz |

| SKU Number | Capacity | Operating Temp | Block or Bath | Price | Quantity | Add to Cart |

| 52100-BLK | .25L | N/A | Bead Block |

305.57

Each

|

||

| 52100-BLU | .25L | N/A | Bead Block |

305.57

Each

|

||

| 52100-GLD | .25L | N/A | Bead Block |

305.57

Each

|

||

| 52100-RED | .25L | N/A | Bead Block |

305.57

Each

|

||

| 52100-SLV | .25L | N/A | Bead Block |

305.57

Each

|

||

| 52120-200 | Single Bath | Ambient +5 to 150 ° C | Dry Bath |

786.21

Each

|

||

| 52200-BLK | .50L | N/A | Bead Block |

473.16

Each

|

||

| 52200-BLU | .50L | N/A | Bead Block |

473.16

Each

|

||

| 52200-GLD | .50L | N/A | Bead Block |

473.16

Each

|

||

| 52200-RED | .50L | N/A | Bead Block |

473.16

Each

|

||

| 52200-SLV | .50L | N/A | Bead Block |

473.16

Each

|

||

| 52230-200 | Double Bath | Ambient +5 to 150 ° C | Dry Bath |

786.21

Each

|

Web Content Viewer